METAL ROD LAMINATION

In the arms of acetate eyewears, a metal core is often

inserted to maintain their strength.

Currently, the "shooting" technique is generally used to insert the core to the arms.

This method involves using a machine to drive the core into the acetate material,

which is very efficient and suitable technique for mass production.

However, before shooting became the common technique,

a skill called "shinbari”, which was carried out by craftsmen by hands was used.

Shinbari (metal rod lamination) is a rare technique in Sabae today

as it requires advanced skills and is time consuming.

In the arms of acetate eyewears, a metal core is often inserted to maintain their strength. Currently, the "shooting" technique is generally used to insert the core to the arms. This method involves using a machine to drive the core into the acetate material, which is very efficient and suitable technique for mass production. However, before shooting became the common technique, a skill called "shinbari”, which was carried out by craftsmen by hands was used. Shinbari (metal rod lamination) is a rare technique in Sabae today as it requires advanced skills and is time consuming.

One of the few Shinbari craftsman left in Sabae

One of the few

Shinbari craftsman left in Sabae

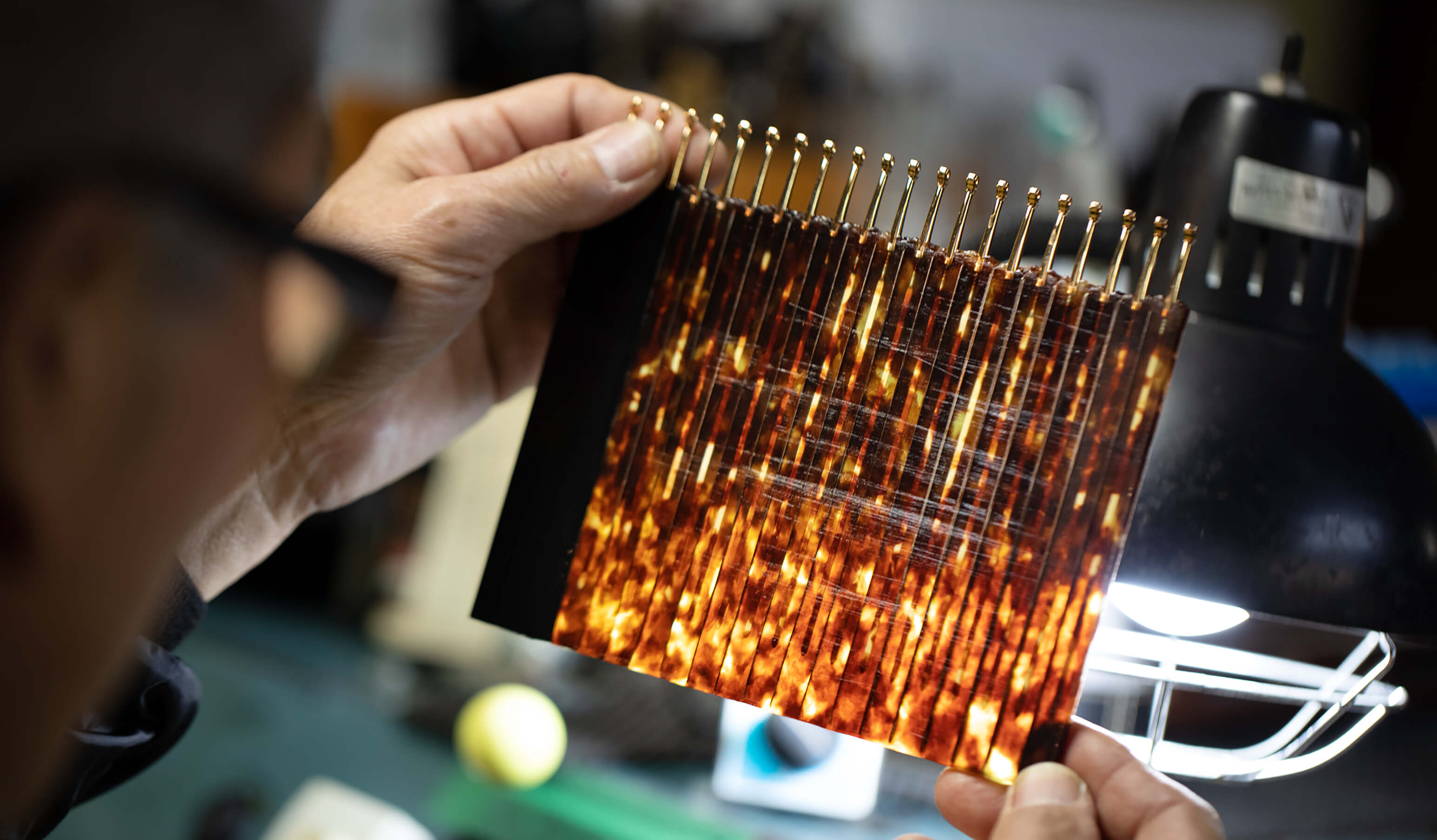

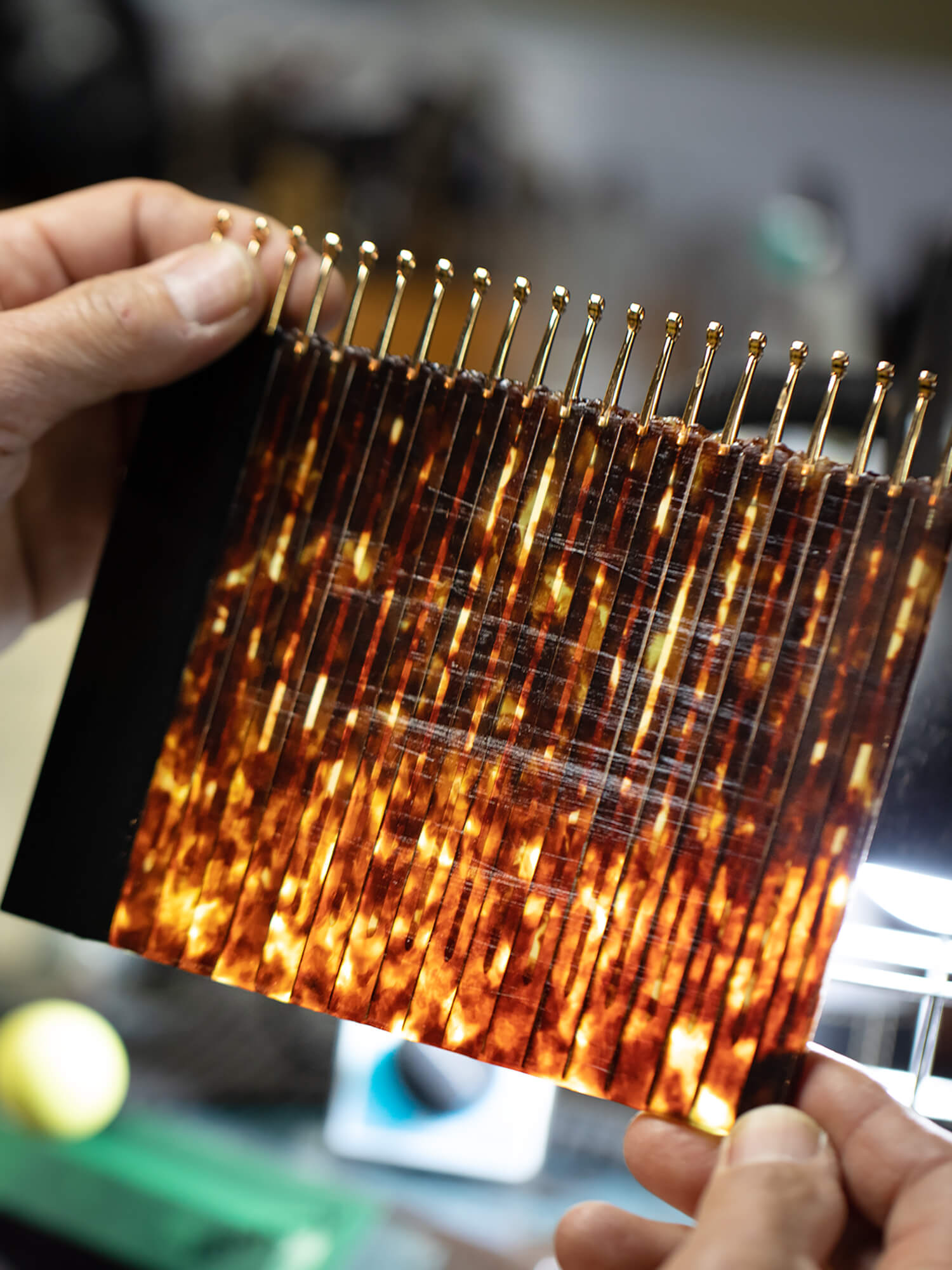

Shinbari is a technique, which a metal core is laminated between two acetate (plastic) sheets that serve as the foundation for making eyewear arms. This technique was used during the era when celluloid was used in making plastic eyewear frames, and now that acetate has become the mainstream, eyewears made using the "Shinbari" technique are becoming very rare. Although many manufacturing processes of eyewear frames have been automated today, "Shinbari" is almost entirely handmade from the start to finish. In addition, acetate is more problematic to laminate than celluloid, making it necessary to have a skilled craftsmanship carrying out the work. Mr. Fujita is a craftsman who is the only one to continue inheriting the fading "Shinbari" technique in Sabae.

The smooth integration of the sheets and core is a beauty that can only be achieved with "Shinbari". The metal core with decorations such as engraving causes ripping, making it difficult to carry out shooting properly with a machine. With Shinbari, the acetate slab is peeled off into two sheets, which then is laminated together with the metal core in between them, making it possible to incorporate beautifully detailed core designs inside. In addition, the combination of metal and plastic made possible by "Shinbari" is superior in terms of durability, allowing the quality to be maintained over a long period of time. "Shinbari" is a technique for creating eyewear frames that combine beauty and durability.

Taking the season and temperature

into account that requires

the craftsman's eyes and sense.

When applying a solvent to acetate sheets and adhering them with heat, surfaces can melt and cause issues such as uneven color depending on the type and color of resin. To avoid these technical issues, it is crucial to not only consider the method of applying the solvent but also to determine the temperature and timing of the bonding itself. During the hot summer months, the drying of the solvent may be accelerated, making the timing even more critical. Additionally, Mr. Fujita uses his own original blend of solvents, which has been adjusted by himself according to the type of resin used.

Not just about skill,

but also knowledge and experience.

After "Shinbari", the strip-like slabs are processed by machines into the shapes of eyewear arms, but for this, skilled craftsmanship is also required. However, with the passing of time, craftsmen who perform this shaping have also become a rare breed. This made Mr. Fujita to start shaping the arms himself three years ago. This is a skill that only became possible as Mr. Fujita has been carrying out Shinbari for about 50 years. When shaping, careful attention must be paid to the cutting tools used, as some resins can crack during the process. Therefore, Mr. Fujita also makes the cutting tools and other equipment he uses by hand. The machines he uses are also antiques devices that are no longer being manufactured, and some of the components are not available, so he performs the maintenance himself as well. This job requires not only skill, but also knowledge and experience of the machines used.

Products that use METAL ROD LAMINATION

Products that use

METAL ROD LAMINATION