MOULD DESIGN

Mould design, which converts 2D designs into 3D technical drawings,

is an essential process that determines the accuracy of molds.

It requires years of experience and technical expertise

to not only transform the designer's envisioned image

into a three-dimensional object,

but also to adjust the shape to one that can be

mass manufactured while considering the cost effectiveness.

Mould design, which converts 2D designs into 3D technical drawings, is an essential process that determines the accuracy of molds. It requires years of experience and technical expertise to not only transform the designer's envisioned image into a three-dimensional object, but also to adjust the shape to one that can be mass manufactured while considering the cost effectiveness.

Turning the designer's vision

into a form that can bemass manufactured.

Turning the designer's vision

into a form that can be

mass manufactured.

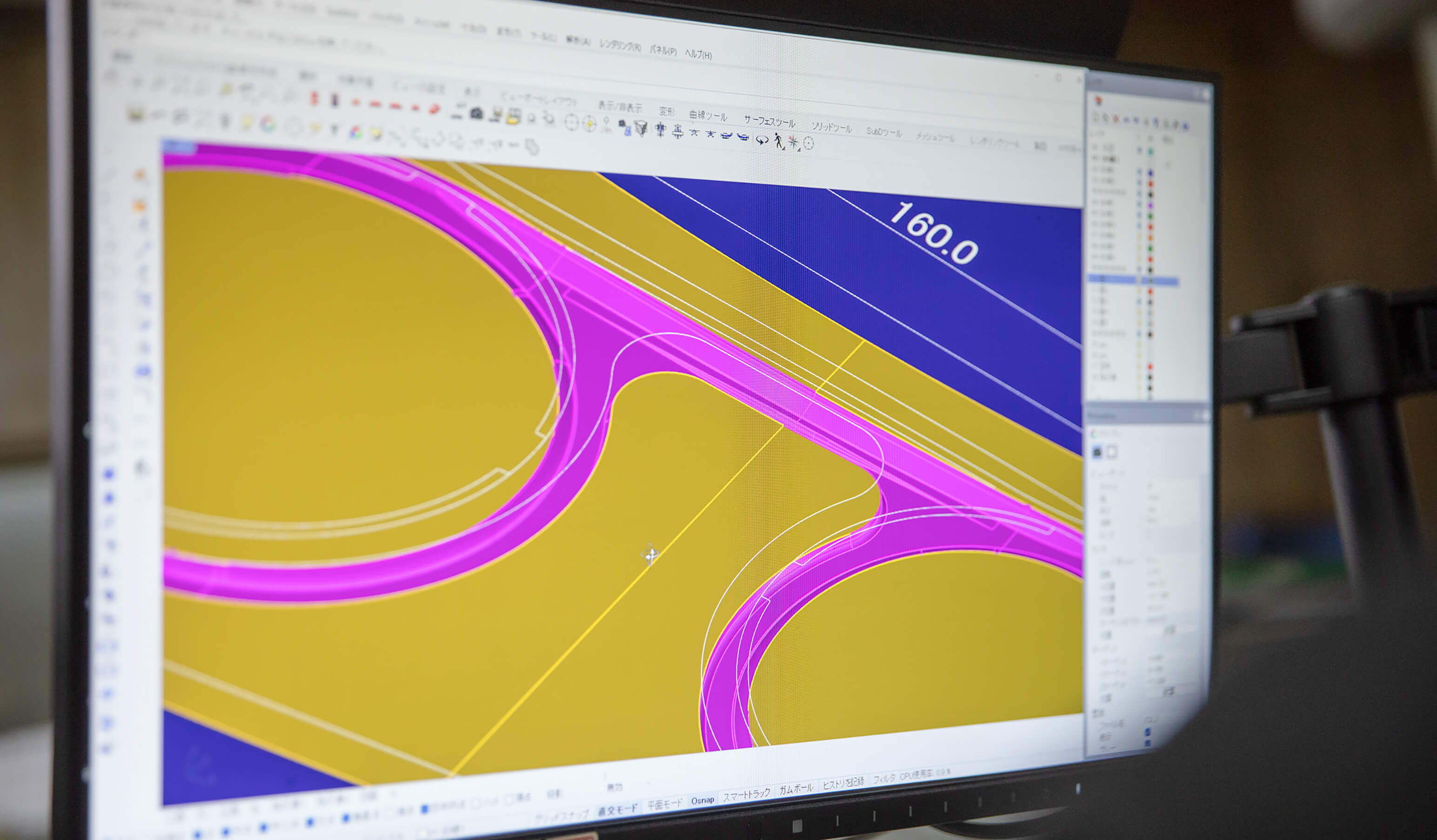

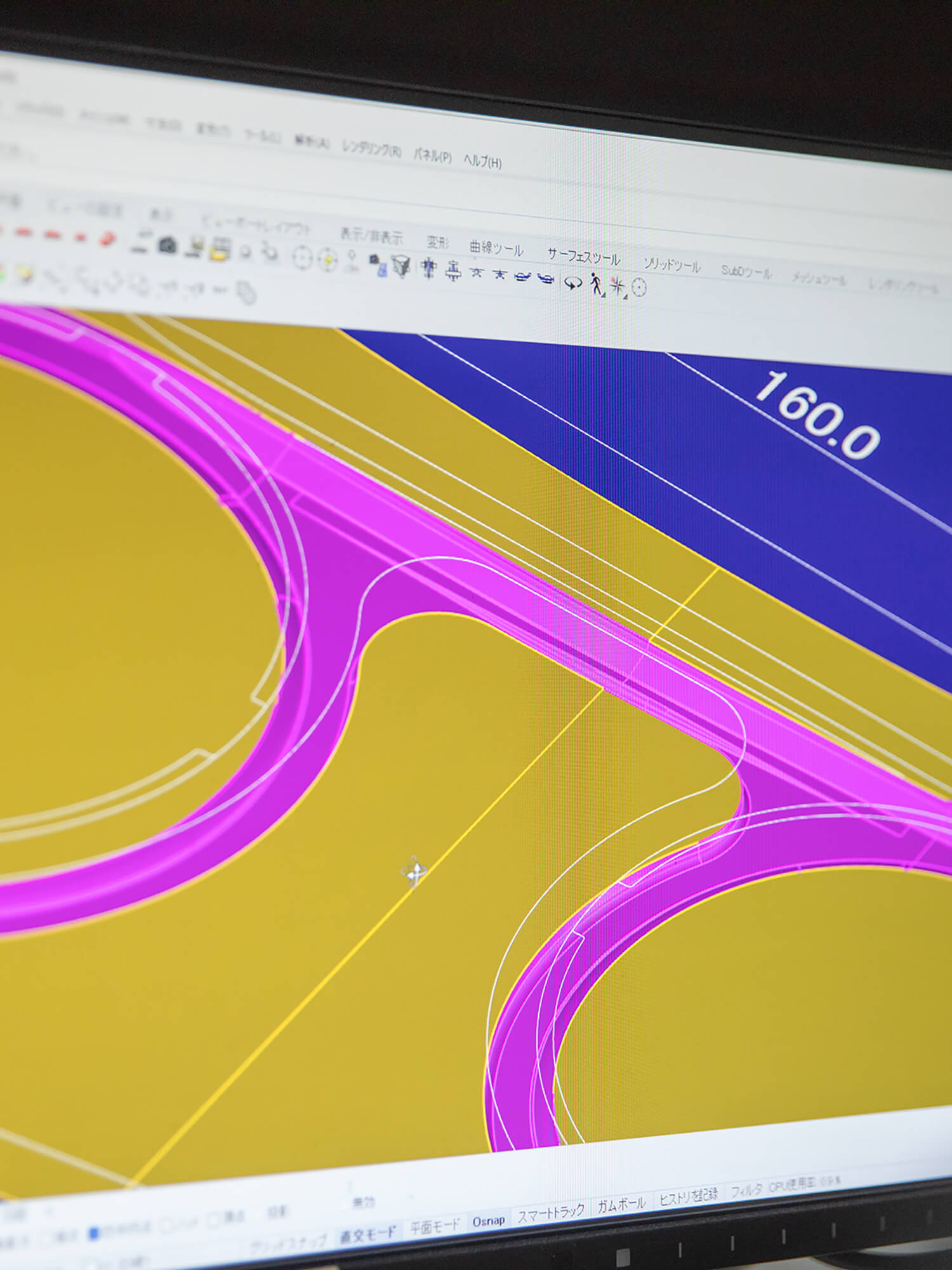

Using a CAD software, a 3D technical drawing is created based on the designer's drawings. In some cases, a "proto frame" (handmade sample) may be provided from the designer. The CAD drawing will then be used to further develop the design into a form that can actually be mass manufactured is used as the basis for mold design. In addition to the ability to accurately understand the direction of the designer's intended design, it requires the skill and experience to express it as close to the original idea as possible while considering mass production.

3D CAD that can improve theaccuracy of molds.

Molds made from 3D data are significantly more accurate than those made solely from 2D drawings. Additionally, molds are actually consumables and can wear out and crack from repeated uses during the production. Having 3D data allows for the reproduction of identical molds as many times as necessary.

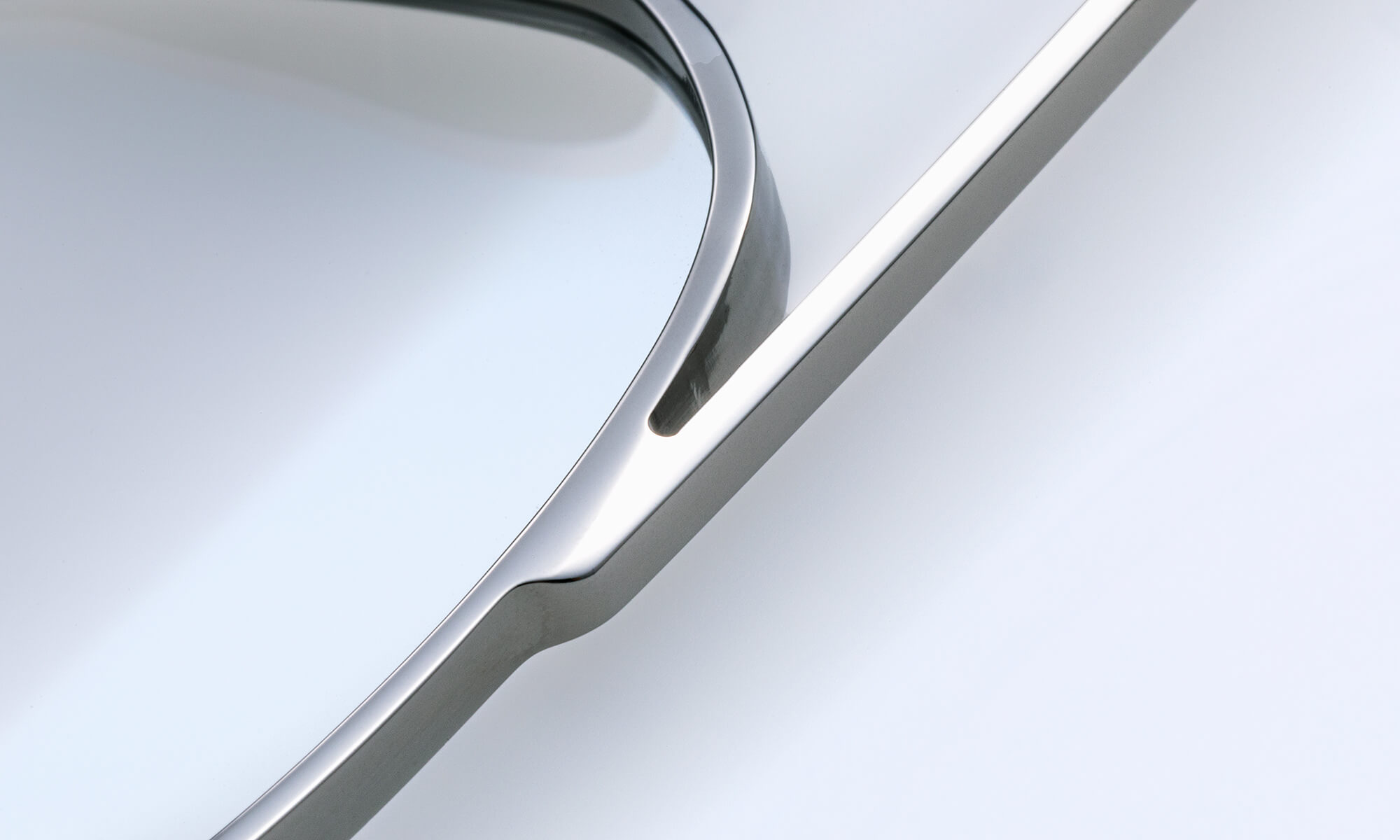

The beauty of lines and surfaces that

coexists with a sense of solidity.

At first glance, eyewear frames may appear simple, but carving a cohesive sense of solidity out of a single solid board is a difficult task as it would usually require multiple components. In addition, to express the beauty of the lines and surfaces within that sense of solidity, the design requires complex connections between surfaces at fine details. In addition to requiring a multiple cutting and pressing processes, the process also includes leaving unnecessary excess material to enhance the strength of the mold press. The excess material is left intentionally and carefully smoothed out to seamlessly connect the parts and bring the design to completion.

Products that use CAD design

Products that use

CAD design