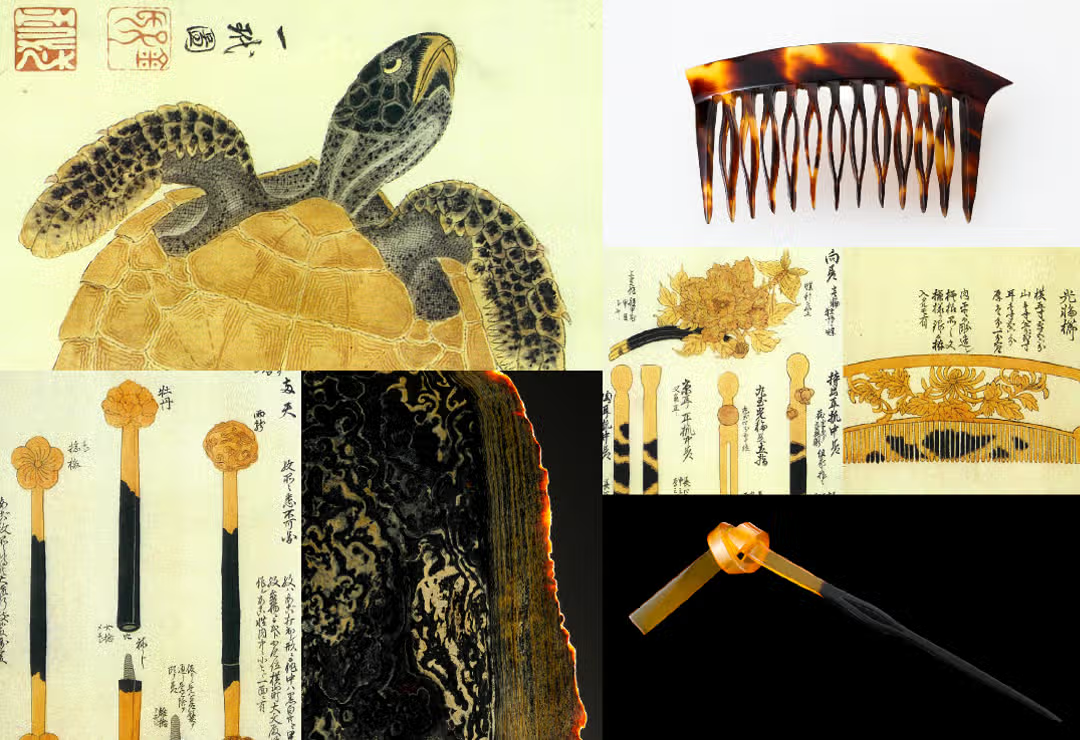

Artisanal process

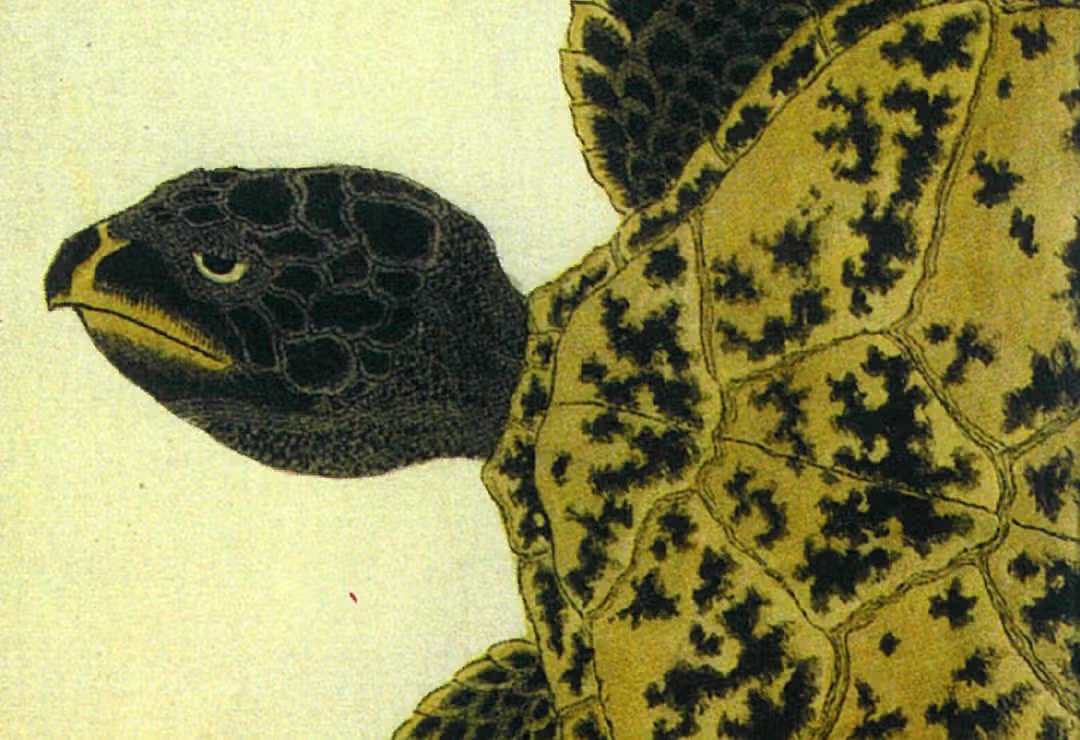

1. Cutting and Preparation

The shell is carefully cut with a fretsaw, and multiple pieces are layered to achieve the desired thickness. Matching the unique patterns and hues of each piece requires the discerning eye and expertise of a skilled artisan.

2. Rough Shaping and Filing

Damaged areas of the shell are first trimmed away using small knives and coarse files. The surface is then polished with cloth-backed sandpaper and other tools, gradually refined to a smooth and even finish.

3. Laminating

The layered pieces are bonded together using water, heat, and pressure.

Although the process may appear simple, it is in fact a crucial step that brings together many different elements. Since each shell has its own unique characteristics, the temperature of the heated iron plates and the precise timing of lamination must be carefully adjusted. This requires the keen intuition and experience of skilled artisans who can recognize and respond to the individuality of each material.

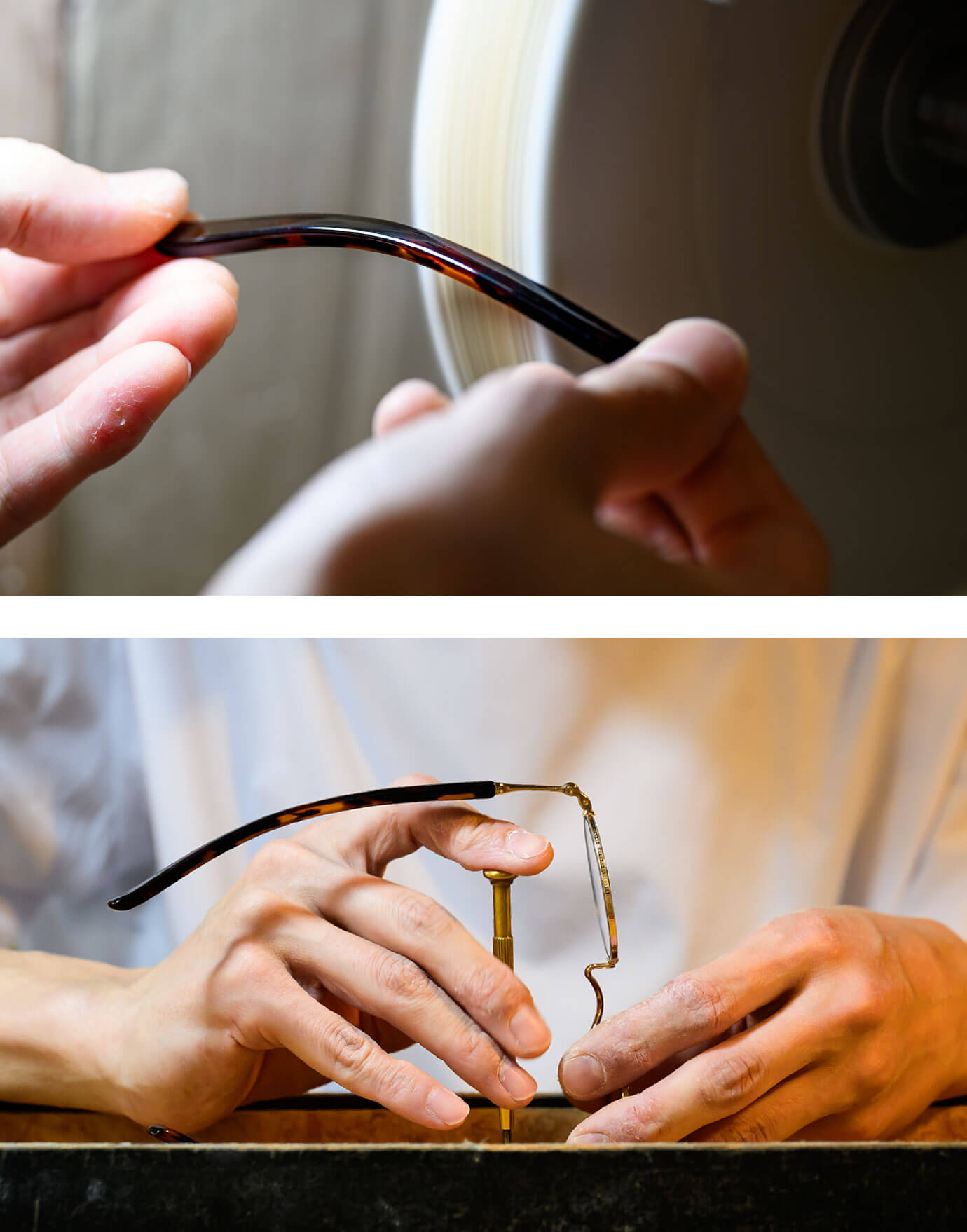

4. Shaping and Forming

The laminated material is refined and shaped using files, small knives, and sandpaper, then bent to match the mold. When necessary, machine cutting is also employed to achieve the desired form.

5. Finishing

The piece is first pre-polished with a finishing machine, then carefully polished with abrasive compounds and a soft cloth to bring out its natural luster. Finally, the part is fitted onto the frame to complete the process.